overhead crane inspection checklist pdf

overhead crane inspection checklist pdf

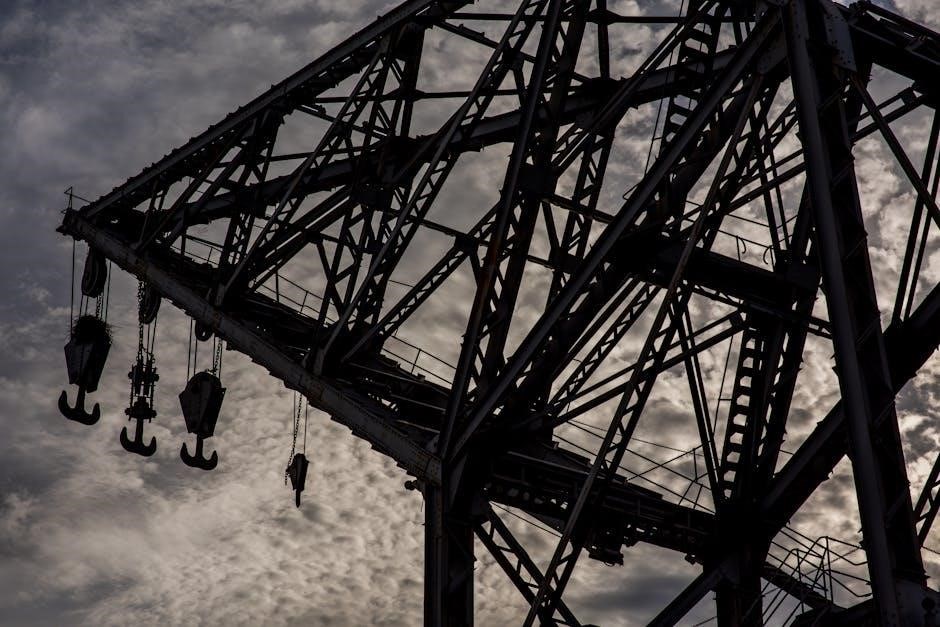

An overhead crane inspection checklist is a critical tool for ensuring crane safety, efficiency, and compliance with regulatory standards․ It guides operators and inspectors through detailed examinations of crane components, such as wire ropes, hoists, and control systems, to identify potential hazards and ensure proper functionality․ Regular inspections help prevent accidents, extend equipment lifespan, and maintain operational integrity․

Overview of the Importance of Regular Inspections

Regular inspections of overhead cranes are essential for ensuring safety, preventing equipment failure, and maintaining compliance with regulatory standards․ They help identify wear and tear, electrical malfunctions, and other potential hazards before they escalate․ By addressing issues early, inspections reduce downtime, extend equipment lifespan, and prevent accidents․ Compliance with OSHA and other regulations further ensures a safe working environment and avoids legal penalties, making regular inspections a critical component of operational efficiency․

Key Components of an Overhead Crane Inspection Checklist

A comprehensive overhead crane inspection checklist includes critical components such as wire ropes, chains, hoists, trolleys, and brakes․ It also covers electrical systems, control panels, and limit switches․ Visual checks for wear, corrosion, and damage are essential, along with functional tests to ensure proper operation․ Additionally, the checklist should address load-testing, lubrication, and safety features like emergency stops; Each component must be evaluated to ensure compliance with safety standards and prevent operational failures․

Regulatory Requirements for Overhead Crane Inspections

Overhead crane inspections must comply with OSHA 1910․179 and other industry standards, requiring daily and monthly checks to ensure safety and operational integrity․ Regular documentation is mandatory․

OSHA Regulations (Section 1910․179)

OSHA’s Section 1910․179 outlines specific requirements for overhead cranes, including daily pre-shift inspections by operators and monthly comprehensive inspections by qualified personnel․ These regulations ensure that cranes operate safely and efficiently․ Non-compliance can lead to severe penalties, so employers must enforce adherence to these standards․ The regulations cover critical components like wire ropes, hoists, and brakes, ensuring that all potential hazards are identified and addressed promptly․

Other Relevant Standards and Guidelines

Beyond OSHA, other standards like ASME B30․2, ANSI B30․17, and CMAA specifications provide detailed guidelines for overhead crane inspections․ These standards cover inspection frequencies, criteria for wire rope replacement, and specific checks for hoist and trolley components․ They also emphasize proper documentation and record-keeping practices․ Compliance with these standards ensures a comprehensive inspection process, addressing both safety and operational efficiency while complementing OSHA requirements․

Daily vs․ Monthly Inspections

Daily inspections ensure immediate identification of potential issues, focusing on visual checks and operational tests․ Monthly inspections provide a more thorough examination, covering critical components like wire ropes and brakes․ Together, these schedules maintain crane safety and efficiency, preventing unexpected downtime․

Daily Operator Inspection Checklist

The daily operator inspection checklist involves checking the crane’s visual appearance, hoist operation, trolley movement, and bridge alignment․ Operators ensure all components are free from damage, wear, or malfunctions․ They verify proper function of brakes, limit switches, and control systems․ Additionally, they inspect wire ropes for kinks or damage and ensure load charts are visible․ Any defects must be documented and reported immediately for corrective action․

Monthly Comprehensive Inspection Requirements

A monthly inspection requires a thorough examination of the crane’s critical components, including brakes, wire ropes, hoist mechanisms, and electrical systems․ Inspectors check for wear, damage, or misalignment and verify proper lubrication of moving parts․ Hydraulic and electrical systems are tested for leaks or malfunctions․ All findings must be documented, and any defects requiring repair are reported for timely action to ensure ongoing safety and compliance with regulations․

Key Components to Inspect

Key components to inspect include wire ropes, chains, hoists, trolleys, and brakes․ These elements are crucial for safe crane operation and load handling, ensuring reliability and compliance with safety standards;

Wire Rope and Chain Inspection

Wire ropes and chains must be inspected for wear, corrosion, and damage․ Look for frayed strands, kinks, or broken links․ Ensure proper lubrication is maintained․ Any damage exceeding acceptable limits requires immediate replacement․ Regular inspections prevent sudden failures during operations, ensuring safety and operational continuity․ Visual checks and hands-on examinations are essential for identifying potential hazards early․ Compliance with standards ensures reliable performance and longevity of crane components․ Regular maintenance extends equipment lifespan and prevents costly repairs․

Hoist, Trolley, and Bridge Components

Inspect the hoist for proper lifting and lowering functionality, ensuring hooks and latches are secure․ Check trolley movement for smooth operation and alignment with the bridge․ Examine bridge components for structural integrity, proper rail alignment, and secure connections․ Lubricate moving parts as needed․ Look for signs of wear, corrosion, or damage that could impair performance․ Ensure all components are functioning within design specifications to maintain safe and efficient crane operation․

Brakes and Control Systems

Inspect brakes for proper holding and emergency stop functionality․ Test control systems for smooth operation and precise responses to commands․ Verify limit switches and load brakes are functioning correctly․ Ensure all electrical connections are secure and free from damage․ Check for proper lubrication of moving parts in braking mechanisms․ Test hoist and trolley controls for consistent performance․ Ensure compliance with OSHA standards for braking and control system safety to prevent operational failures and accidents․

Safety Precautions During Inspections

Ensure the crane is on stable ground and properly supported․ Disconnect power and apply lockout/tagout procedures․ Wear PPE, including hard hats and safety glasses․ Verify no loads are suspended before starting inspections․ Check for proper ground conditions and stability to prevent accidents during the process․

Proper Lockout/Tagout Procedures

Proper lockout/tagout (LOTO) procedures are essential for ensuring crane inspections are conducted safely․ Disconnect power sources and apply approved locks or tags to prevent accidental operation․ Verify energy isolation and use crane mats or supports to stabilize the equipment․ Ensure all moving parts are secure and no loads are suspended․ Follow OSHA guidelines and train personnel to adhere strictly to LOTO protocols during inspections to prevent accidents and compliance violations․

Personal Protective Equipment (PPE) Requirements

Inspectors must wear proper PPE during overhead crane inspections to ensure safety․ This includes hard hats, safety glasses, gloves, and steel-toe boots․ High-visibility clothing is also recommended․ Respiratory protection may be required in dusty environments․ Ensure all PPE meets OSHA standards and is in good condition․ PPE is non-negotiable for protecting inspectors from potential hazards during the inspection process․ Never start an inspection without proper protective gear․

Documenting Inspection Findings

Record all inspection results in detail, including dates, checkmarks, and notes on defects․ Ensure findings are signed and stored for compliance and future reference․ Accurate documentation is key to accountability and safety standards․

How to Complete the Inspection Checklist

Begin by reviewing the checklist and ensuring all items are clearly understood․ Conduct the inspection systematically, checking each component visually and operationally․ Note any defects or abnormalities, providing detailed descriptions․ Ensure all findings are accurately recorded, with dates and signatures included․ Submit the completed checklist to supervisors for review and follow up on any required repairs or maintenance․ This structured approach ensures thoroughness and accountability․

Reporting Defects and Necessary Repairs

Document all defects found during inspections, noting their severity and location․ Include detailed descriptions of issues, such as wear, damage, or malfunctions․ Notify supervisors immediately for critical defects, ensuring operations are halted if safety is at risk․ Submit the completed checklist with repair recommendations and track progress until issues are resolved․ Maintain records of all reports and repairs for future reference and compliance audits․ This ensures accountability and safety․

Adhere to manufacturer guidelines and regulatory standards for inspections and maintenance․ Implement a preventive maintenance schedule to address wear and tear proactively․ Train personnel on proper inspection techniques and safety protocols․ Use high-quality replacement parts and ensure timely repairs to prevent equipment downtime․ Regular lubrication of moving parts and thorough documentation of maintenance activities are essential for optimal crane performance and longevity․ Always follow lockout/tagout procedures during servicing․ Continuous monitoring and adherence to these practices ensure operational safety and efficiency, minimizing risks and extending the crane’s service life․ Proper storage of maintenance records and checklists is crucial for compliance and future reference․ Regular audits of maintenance processes help identify and address any gaps or inefficiencies promptly․ By prioritizing these best practices, facilities can maintain reliable overhead crane systems and uphold workplace safety standards․ Developing a structured maintenance schedule is crucial for overhead crane reliability․ Plan daily, monthly, and annual inspections based on usage and manufacturer guidelines․ Ensure lubrication of moving parts, thorough wire rope inspections, and checks on hydraulic and electrical systems․ Schedule professional inspections annually or as required by regulations․ Maintain detailed records of all maintenance activities for compliance and future reference․ Promptly address identified issues to prevent equipment failure and downtime․ Regular maintenance ensures safety, efficiency, and longevity of the crane system․ Proper training of crane operators is essential for effective inspections․ Operators should be educated on OSHA regulations, inspection checklists, and safety protocols․ Hands-on training ensures they understand how to identify wear, test controls, and document findings accurately․ Regular refresher courses help maintain proficiency and adapt to new standards․ Training records should be kept to verify compliance and continuous competency․ Well-trained operators contribute to safer operations, reduced downtime, and overall crane reliability․ Wear and tear on moving parts, such as wire ropes, hoist chains, and sheaves, is a common issue identified during inspections․ Over time, these components can degrade due to friction, heavy loads, and environmental factors․ Regular lubrication and visual checks are essential to prevent excessive wear․ Ignoring these issues can lead to equipment failure, safety hazards, and costly repairs․ Inspectors must document any signs of wear and recommend timely maintenance or replacements to ensure smooth crane operation․ Electrical and hydraulic system malfunctions are critical issues often detected during crane inspections․ Faulty wiring, hydraulic leaks, or control system failures can lead to operational disruptions and safety risks․ Inspectors must check for signs of wear, corrosion, or damage in electrical components and hydraulic hoses․ Proper functioning of these systems is vital for smooth crane operation․ Addressing these issues promptly ensures reliability, prevents downtime, and maintains workplace safety, avoiding potential accidents and costly repairs․ A checklist ensures thorough inspection of all critical components, preventing oversights and enhancing safety․ It streamlines the process, ensuring compliance with regulations like OSHA’s Section 1910․179․ By systematically evaluating wire ropes, brakes, and controls, checklists help identify wear and tear early, preventing accidents․ They also promote a culture of safety and accountability, ensuring cranes operate reliably and efficiently, while extending equipment lifespan through proactive maintenance․ Adhering to overhead crane inspection checklists is vital for maintaining compliance with OSHA and other regulatory standards․ Regular inspections ensure safety by detecting potential hazards early, preventing accidents, and reducing downtime․ Proper documentation of findings and prompt repairs are essential for accountability and operational integrity․ By prioritizing safety and compliance, organizations safeguard their workforce, equipment, and reputation, fostering a culture of responsibility and reliability in crane operations․

Best Practices for Maintaining Overhead Cranes

Scheduling Routine Maintenance

Training Operators on Inspection Procedures

Common Issues Identified During Inspections

Wear and Tear on Moving Parts

Electrical and Hydraulic System Malfunctions

Summarizing the Importance of a Checklist

Final Thoughts on Compliance and Safety